TWILL JACKET FR + AT + EA + ANTI-ACID + NIGHT VISIB.

61,70€ Taxes not included

COMPOSITION: 87% Cotton, 12% Polyamide and 1% antistatic fiberTYPE OF FABRIC: Satin 4/1 THICKNESS: 260gr / m2

To add a custom logo Click here

DESCRIPTION:

- Fireproof, Antistatic, Electric Arc, Antacid, Welding and Night Visibility Jacket.

- High neck garment.

- Two patch pockets on the chest.

- Rubberized cuff and velcro strap adjustment.

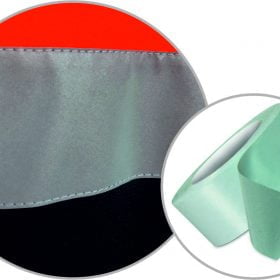

- Two silver gray 5cm wide sewn reflective bands around the arms and chest.

- Yellow Reflective AV band option ( consult for minimum order )

FIRE-RESISTANT, ANTISTATIC, ARC, ANTI-ACID, WELDING AND NIGHT VISIBILITY PROPERTIES:

This product has been manufactured following the requirements of the EU Regulation 2016/425, for its basic use, according to the standards:

· EN ISO 11612: 2015 Protective clothing against heat and flame.

EN 1149-5: 2018. Protective clothing with electrostatic properties.

· IEC 61482-1-1: 2019 Protective clothing against the thermal risk of a Electric arc .

· EN 13034: 2005 + A1: 2009 Repellency and penetration of liquids .

· EN ISO 11611: 2015 Protective clothing used during welding and related processes.

EN 17353: 2020 Type B2 Enhanced visibility clothing for medium risk.

PERMANENT FIREPROOF:

Defines the performance of the garments to protect the entire body from heat and flames; defines the requirements for overalls and 2-piece sets thanks to the use of “ad hoc” materials and specific design requirements that guarantee a level of performance to meet the standard, being regulated by different values of heat resistance.

Performance levels according to EN ISO 11612: 2015:

Limited flame spread: A1, A2

There is no destruction to the edges.

There is no hole formation.

There is no merger.

Post-glow time ≤ 2 s.

Post-combustion time ≤ 2 s.

| Convective heat: B1 | ||

| Performance level |

Intervals HTI24 | |

| Min | Max | |

| B1 | 4 | <10 |

| B2 | 10 | <20 |

| B3 | ⋝20 | |

| Radiant Heat C1 | ||

| Performance level | Intervals HTI24 | |

| Min | Max | |

| C1 | 7 | <20 |

| C2 | 20 | <50 |

| C3 | 50 | <95 |

| C4 | ⋝95 | |

| Cast iron splash: E3 |

||

| Performance level | Cast iron splash (g) | |

| Min | Max | |

| E1 | 60 | <120 |

| E2 | 120 | <200 |

| E3 | ⋝200 | |

| Contact heat: F1 | ||

| Performance level | Threshold time (s) |

|

| Min | Max | |

| F1 | 5 | <10 |

| F2 | 10 | <150 |

| F3 | ⋝150 | |

PERMANENT ANTISTATICS:

Specifies material and construction requirements for electrostatic-dissipating garments used as part of a total grounding system to prevent discharges that can cause fires.

Resistance to the accumulation of electrostatic charges according to EN 1149-5: 2018: S> 0.2 or t50< 4s

- The person wearing electrostatic dissipative protective clothing must be properly grounded. The resistance

between the person and the ground must be less than 108Ω, eg through the use of suitable footwear. - Electrostatic-dissipative protective clothing should not be removed while in the presence of flammable or flammable atmospheres.

explosives or when handling explosive or flammable substances. - The garment must be fully buttoned.

- The use of electrostatic dissipative protective clothing should not be done in oxygen-enriched atmospheres without approval.

prior to the security officer. - The dissipative behavior of electrostatic dissipative protective clothing can be affected by wear, tear,

washes and possible contamination. - Electrostatic-dissipative protective clothing must permanently cover non-compliant materials during use

normal (even in a crouched position and on the move).

ELECTRIC ARC:

This regulation specifies the performance of the garments designed to protect the whole body against the thermal risks of an electric arc due to an accidental and unexpected short circuit in power plants.

IEC 61482-1-1: 2019 Live work. Protective clothing against the thermal risk of an electric arc. Determination of the arc characteristic (ELIM, ATPV and / or EBT)

REPELLENCE AND PENETRATION OF LIQUIDS:

Repellency and penetration of liquids: EN 13034: 2005 + A1: 2009. It defines the performance and minimum safety requirements of the garments studied to guarantee limited protection against liquid chemical agents.

In the event of accidental splashing, during use, of chemicals or flammable liquids on clothing covered by this International Standard, the user must carefully remove the clothing, ensuring that the chemical or liquid does not come into contact with any part. of the skin. The clothing will then be cleaned or removed from service. The partial body protections of type PB [6] have not been subjected to the full suit test.

Repellency and penetration of liquids: EN 13034: 2005 + A1: 2009

| Liquids tested | Repellency to liquids | Resistance to liquid penetration |

| H2SO4 (30% weight) | 3 of 3 | 3 of 3 |

| NaOH (10% weight) | 3 of 3 | 3 of 3 |

| 1-Butanol | 3 of 3 | 2 of 3 |

Resistance to penetration of liquids in spray form (EN 13034: 2005 + A1: 2009): COMPLIES

WELDING AND RELATED PROCESSES:

EN ISO 11611: 2015 Protective clothing used during welding and related processes.

Establishes minimum safety requirements and test methods for protective clothing (including hoods, aprons, sleeves, and gaiters; hand protection not included) designed to protect the wearer’s body, including the head and feet, and that it must be worn during welding and related processes with comparable risks.

Protective clothing used during welding and related processes according to EN ISO 11611: 2015:

• See Guide to prevention of risks in welding work.

• Garment protects against flames, molten metal splashes, contact heat, convective heat, radiant heat and electrical contact

short-term accidental.

• Additional partial body protection may be necessary, eg for indoor welding.

• The garment is only intended to protect against brief unintentional contact with charged parts of an arc welding circuit and by

Therefore, additional layers of electrical insulation will be required when there is an increased risk of electrical shock.

• Aprons should cover the front of the wearer’s body at least from seam to side seam.

• When additional partial protective garments are used, the basic garment must be at least Class 1.

N ORMA UNE-EN 17353: 2020 – PROTECTIVE CLOTHING – IMPROVED VISIBILITY EQUIPMENT FOR MEDIUM RISK SITUATIONS

It includes the requirements and test methods for the design of garments and accessories intended for situations of medium risk due to low visibility, and which provide some visibility to the users who wear them.

It is the Standard that completes the regulation of protective clothing for low visibility risk situations. Until now, there was only the EN ISO 20471: 2013 Standard that regulated clothing for HIGH RISK situations, that is, where the user passive (worker on foot located in a zone where vehicles are at risk of being run over during the day or night) is on a road with vehicles traveling with a speed from less than 30 km / h (Class 1) to more than 60 km / h (Class3).

This new Standard UNE-EN 17353: 2020 regulates clothing and accessories that improve visibility in MEDIUM RISK situations, where the user passive (on foot) is on a road where vehicles circulate at less than 15 km / h, or that the user active (person who is on the road, who is part of the circulation and who keeps his attention focused on the traffic, that is, he is driving some type of vehicle) is on a road with vehicles that circulate at a speed equal to or less than 60 km / h.

This Standard distinguishes between clothing and accessories for use in various situations:

– at night (Class B, reflective elements), which is subdivided into three categories: the B1 for hanging accessories of reflective material; the B2 for armbands and garments with reflective material only on the sleeves; and the B3 for garments with reflective material only on the torso, or on the torso + extremities (sleeves and legs)

| Type A Daylight |

Type B Dark conditions |

Type AB Daylight, twilight and dark conditions |

| Equipment using fluorescent material | Equipment using retroreflective material | Equipment using fluorescent material and retroreflective material or combined perfomance material |

| B1 (free hanging) | ||

| B2 (limbs) | AB2 | |

| B3 (on torso or torso and limbs) | AB3 |

The reflectance and fluorescence requirements of reflective elements and fluorescent fabrics are the same as in EN ISO 20471. Protective equipment certified under this Standard falls within Category III of PPE classification according to EU Regulation 2016/425.

Sizing

At Multinormwear we adapt to your size needs with our multinorm garments.

We have a very wide size in our range of products:

- From the size 2XS to 4XL

DETERMINE YOUR SIZE:

This table will help you determine the size you are looking for.

Reflective Bands

Fire retardant retroreflective material

The reflective tape we use is manufactured following strict quality control procedures and has been certified in accordance with the performance levels required by the standards. IN 20471 (High visibility signaling clothing) and EN 469 (Protective clothing for firefighters).

Owns a excellent fastness to washing , has been tested to support 50 cycles from wash to 60ºC . It also features a very good resistance to heat and fire .

Recommendations

Recommendations for use:

- Indicated for industrial activities where the user is subjected to brief contact with a small flame. Convective heat with power less than or equal to 80 kW / m2

- Radiant heat sources of power less than or equal to 20 kW / m². Heat by contact with surfaces at temperatures of 250ºC.

- In the event of molten metal splash, the user must immediately leave the workplace and remove the garment. In case of splashing, if the garment is used next to the skin, it may not eliminate the risk of burns.

- For the protection of the whole body, the protective clothing must be worn in a closed state and together with other suitable protective equipment against the same risks that PPE presents: pants, helmet with a face protection screen, protective gloves and boots. .

- Environmental conditions and workplace hazards must be considered.

- Achieving the performance of the garment requires that it be properly closed and adjusted.

Recommendations against misuse:

- This PPE should never be used against risks other than those described above.

- Poor maintenance of the garments can modify their performance.

- Dirty clothes can lead to a reduction in protection.

- Dirt or molten debris adhering to the garment can impair its performance.

- Do not remove the garment when in explosive or flammable atmospheres or when handling explosive or flammable substances.

- An increase in the oxygen content of the air can considerably reduce the flame protection of the garment. Care should be taken when welding in confined spaces, for example if the atmosphere is likely to become enriched with oxygen.

- The level of flame protection will be reduced if welders’ protective clothing is contaminated with flammable substances.

- The electrical insulation provided by clothing will be reduced if the clothing is wet, dirty, or soaked with sweat.

- This garment does not protect the neck, legs, head, hands and feet.

- The garment must not be worn with other garments under it, which are non-fire retardant and / or made of hot-melt material.

- The tears must not be repaired by the user, a flammable thread or a probable part reactivatable with heat by fusion could be very dangerous in the case of an explosion by flame.

Maintenance:

- Maximum washing temperature 60ºC.

- Do not use bleaches.

- Drum drying allowed. Normal temperature; maximum emission temperature 80ºC.

- Ironing at the maximum temperature of the plate below 110ºC.

- Professional dry cleaning not allowed.

- Warning: In the event of accidental splashing of chemical or flammable liquids on clothing, the user should remove the clothing immediately, ensuring that no contact with any part of the skin occurs. Afterwards, the clothes must be cleaned and taken out of service.

- Storage:Store the garment avoiding unnecessary sun exposure and in dry places, protected from any aggressive agent.

- Packaging: Plastic bag.