TWO TONE ANTISTATIC HV SHORT SLEEVE T-SHIRT

From: 23,30€ Taxes not included

COMPOSITION: 49% Polyester, 49% Cotton, 2% Fil. AntistaticTYPE OF FABRIC: Point type "pique" or "granite"THICKNESS: 210gr / m2

To add a custom logo Click here

DESCRIPTION:

- Two-tone high visibility antistatic short sleeve t-shirt.

- 1 × 1 stretch fabric collar.

- Optionally it can incorporate a fluorescent yellow chest pocket.

- With reflective bands around the torso.

Standard EN ISO 13688/13 (general requirements for Protective Clothing): Complies

Category according to EU Regulation 2016/425 (requirements on the design and manufacture of PPE to guarantee the protection of the health and safety of users): Category II

EN 1149-5/08 norm (protective clothing with electrostatic properties) Cumplies

| EN 1149-5:2018 ANTISTATIC | Value specified by norm | Value obtained from the fabric |

| ELECTRICAL FIELD INTENSITY(S) | >0.2 | 0.51 |

| SEMI-DISSIPATION TIME (t50) | <4 sec | <0.01 sec |

Rule EN ISO 20471/13 (high visibility protective clothing): Class 1

| CLASS 1 | Value specified by the norm | Value obtained from garment “S” size |

| HIGH VISIBILITY BACKGROUND MATERIAL SURFACE | > 0.14 m2 | 0.40 m2 |

| REFLECTIVE MATERIAL SURFACE | > 0.10 m2 | 0.10 / 0.18 m2 |

Sizing

At Multinormwear we adapt to your size needs with our multinorm garments.

We have a very wide size in our range of products:

- From the usual sizes that go from the XS to 3XL

- Range of extra-large sizes, ranging from 4XL to 7XL

DETERMINE YOUR SIZE:

This table will help you determine the size you are looking for.

Measure below the armpits, the most prominent part of your contour (chest, waist or hips).

Keep the tape measure horizontal and, in the table you will find the correspondence in size.

(Tolerance margin of + – 2 cm)

Reflective Bands

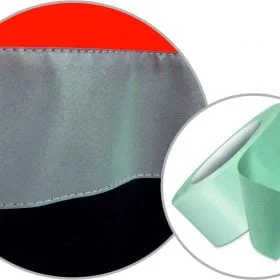

1) SEWED REFLECTIVE STRIP:

Fire retardant retroreflective material

The reflective tape we use is manufactured following strict quality control procedures and has been certified in accordance with the performance levels required by the standards. EN 471: 2003 (High visibility signaling clothing), ANSI / ISEA 107-2004 (High Visibility Safety Clothing) and EN 469: 2005 (Protective clothing for firefighters).

The tape is made up of different layers that allow you to combine a high level of reflectivity with good washing resistance, low temperature performance, abrasion resistance (according to the EN-471 standard) and limited flame spread (according to the definition contained in the EN-469 standard). The light reflective layer of this tape is composed of partially aluminized mbeads ™ and the substrate material is fire resistant polycotton.

Owns a excellent fastness to washing , has been tested to support 50 cycles washing at 60ºC and 5 dry cleaning cycles. It also features a very good resistance to heat and fire .

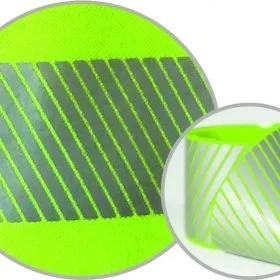

2) DISCONTINUOUS THERMAL FIXED BAND:

Reflective Material – Flame Resistant Band

This reflective material is designed for use in protective clothing that requires flame resistance. Used properly, this reflective material helps to improve user visibility in night conditions or low visibility when illuminated through the headlights of a vehicle, returning the light to the original source and reaching the driver’s eye.

It is composed of retroreflective lenses attached to an adhesive that is activated by heat. The band is 50.8 mm (2 inches) wide.

It is certified under the updated versions of EN ISO 20471 for High Visibility garments.

Recommendations

Instructions for use:

This PPE has been conceived to facilitate the dissipation of the electrostatic charges accumulated in the body and for the visibility of the user under the headlights of a vehicle in low light conditions.

· Ground connection: The person wearing electrostatically dissipative protective clothing must be grounded, either by electrostatically dissipative footwear or by any other suitable means. The resistance between the person and the earth must be less than 108Ω

It should not be removed , or remove in the presence of flammable or explosive atmospheres, or when handling flammable or explosive substances.

For the protection of the whole body, protective clothing should be worn closed and as close to the body as possible, and with other suitable protective equipment. Clothing must be grounded through direct contact with the wearer’s body or through a direct ground connection.

· The electrostatic dissipation resistance and high visibility properties of this protective clothing can be affected by wear and tear, laundering and possible contamination.

· The user should not put on any other garment unless it has the same electrostatic dissipation and high visibility properties as the latter.

Electrostatic dissipative protective clothing must permanently cover all non-dissipative materials during normal use (including bending and movement)

Recommendations against misuse:

· This PPE should never be used against risks other than those described above.

· Poor maintenance of the garments can modify their performance.

· Dirty laundry can lead to reduced protection.

· The tears must not be repaired by the user.

· Limits of use: This protective clothing must NOT be used in oxygen-rich atmospheres without the prior approval of the technician responsible for safety.

Washing recommendations:

![]()

MAX. 25 washes

· Washing at a maximum temperature of 30ºC.

· Bleaching is not allowed.

· Iron to 1 point.

· Dry cleaning is not allowed.

· Tumble drying is not allowed.

Storage: Store the garment avoiding unnecessary sun exposure and in dry places, protected from any aggressive agent.

The antistatic and high visibility properties of this garment are permanent, so the useful life of the PPE will be a direct function of use and care, so it can be used without prior limit as long as no evidence of deterioration is observed. Despite this, its replacement is recommended after a period of one year of use.